Press release:

Imagine a classroom where students can design and manufacture an iPhone case, whistles or even a part for an RC car for pennies on the dollar.

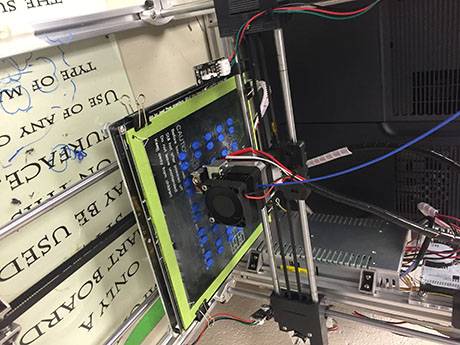

It's happening at Elba Central School with the help of a 3-D printer, which the school acquired as part of Genesee Valley BOCES Make and Take Workshop back in February.

A 3-D printer works much like a more familiar 2-D text and picture printer.

"3D printers take a digital file and turn it into a three-dimensional object layer by layer," said Elba's Technology coordinator, Mary Beth Stacy. "Engineering classes can print their designs and see if they will actually work instead of just assuming that it will. The printer we have can actually print many of it's own parts."

"The students design the objects using CAD software and then print it," Stacy said. "Sometimes the design works and sometimes it fails. Great life lessons about learning from their mistakes and not giving up are being reinforced, along with critical thinking and problem solving skills."

Instead of ink, users can choose their own material. Most educators use a low-cost plastic filament.

"The students are really excited to see it," Kevin Rombaut, technology teacher at Elba Central School said. "It allows them to see rapid prototyping and modeling. It gives them actual objects that they can see and hold other than just a computer rendering or imagination.

"It allows them to create parts and/or objects and to re-invent. I had one student break a part on their RC vehicle. They took it, drew a new one, changed the design to offer more support, and printed a new part out."

Elba Central School is doing what it can in keeping current with technology to help their students succeed in the future.

As Stacy pointed out, "Our students' futures will have technology embedded in their daily lives."